Geopolymer, Economically environmentally friendly cement

Recent studies focus on using geopolymers as environmentally friendly binders for soil stabilization to mitigate the greenhouse effect, but the impact of CO2 exposure on the mechanical properties of geopolymer-stabilized soils is less explored. Research on sandy soil stabilized with volcanic ash-based geopolymer showed that CO2 exposure significantly increased compressive strength, with optimal results at 100 kPa CO2 pressure, and highlighted the importance of binder content, carbonate content, and curing conditions.

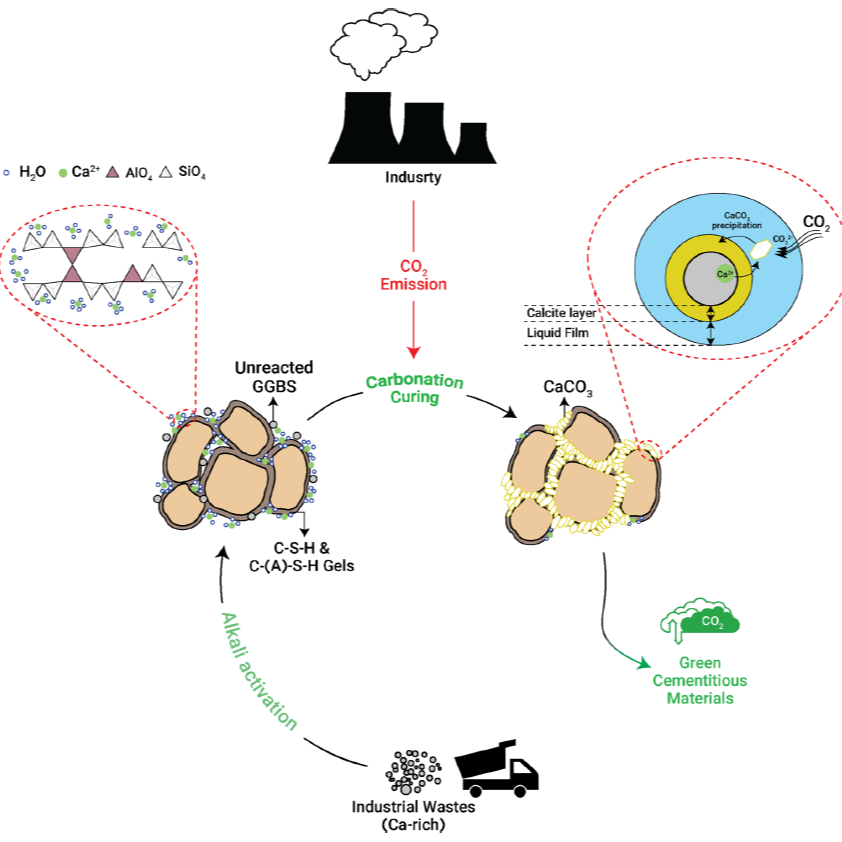

In order to elaborate on the CO2 exposure effect, this figure proposes a hypothetical project as a landfill where a considerable amount of CO2 is released. Therefore, the carbonation process can be implemented to stabilize the cover layer of the landfill. This figure illustrates the carbonation in four general stages. (a) shows the soil particles exposed to CO2 gas. In the second stage, the volcanic ash and an alkali activator (including water) are added to the soil, as shown in the figure. The alkali activator like water activates the geopolymer based on volcanic ash by breaking the bond Si-O and Al-O, resulting in forming N-A-S-H gel as shown in (c). Note that the CO2 cannot react with free ions like Ca2+ directly, so the CO2 dissolved in a thin layer of moisture called diffusion length surrounding the volcanic ash particle which leads to the formation of H2CO3 as shown in the figure. In the fourth and final stage, carbonation products like CaCO3 are formed and bind the soil particles in combination with N-A-S-H gel in geopolymer base volcanic ash.

Mitigate the Greenhouse Effect

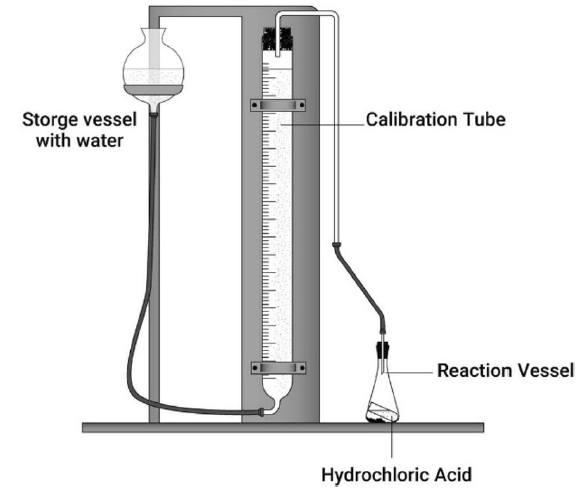

Portland cement, widely used in soil stabilization, releases significant CO2, prompting the need for green alternatives like ground granulated blast furnace slag (GGBS). Accelerated carbonation, which converts CO2 into carbonate minerals, is studied to reduce the industry’s carbon footprint. This study investigates the impact of accelerated carbonation on the unconfined compressive strength (UCS) of soil stabilized with alkali-activated slag under ambient and oven-curing conditions.

Factors examined include:

- Curing time

- Binder content

- Relative density

- Carbonation pressure (100, 200, and 300 kPa)

A calorimeter test measured carbonate generation, reflecting CO2 sequestration in soil. The key findings showed that carbonated samples exhibited higher strength than non-carbonated ones, though a slight decrease in UCS was observed with increased CO2 pressure. The carbonate content directly correlated with UCS, explaining the higher strength of carbonated samples. Additionally, ambient curing was more favorable for GGBS-stabilized samples due to better moisture availability.

Results from XRD, SEM, and FTIR analyses indicated that the strength development was primarily due to the formation of CaCO3, which enhanced the densification of solidified materials.

Physical modeling of Nailing

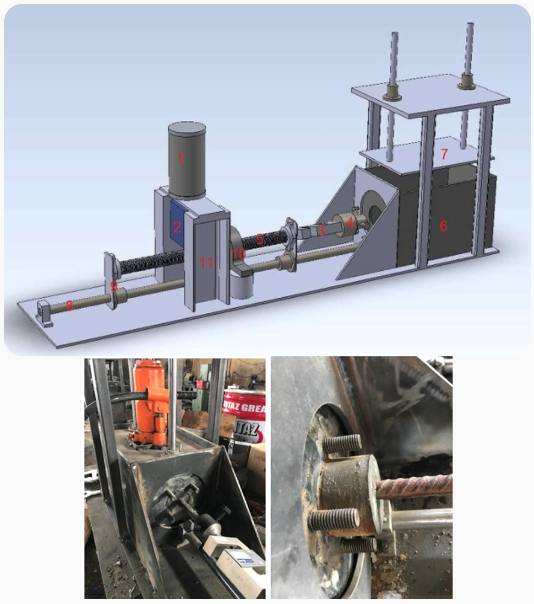

Portland cement is widely used in construction, but its production causes significant environmental pollution, including CO2 emissions and high water usage. Geopolymer products are emerging as a promising alternative due to their superior mechanical and chemical properties. This study investigates the potential of geopolymers as replacements for Portland cement. Optimal mixing designs were determined using uniaxial compressive strength and flow table tests.

Key points:

- Geopolymers were tested as a substitute for cement grout in soil nailing, a common method for stabilizing soil excavations and slopes.

- Pullout tests evaluated the interaction between soil and grout, considering curing conditions and environmental factors (temperature, humidity, and overburden pressure).

- Findings showed that:

- Geopolymer samples generally had lower pullout forces compared to cement samples.

- Increasing temperature improved the pullout force in geopolymer samples but decreased it in cement samples.

- Geopolymer samples may need additives like sodium silicate to achieve suitable pullout force and proper soil interlocking.

Full-scale and small-scale field investigation of jet grouting columns

Jet-grouted columns were tested both in full-scale and small-scale experiments to assess their strength and properties. Full-scale columns were installed at a site in Astara to improve silty sand, and small-scale columns were used to explore the diameter-strength relationship.

Key findings:

- Correlations between unconfined compressive strength (qu) and technical parameters were established.

- Columns with sea water showed better short-term mechanical properties, though long-term differences were minimal.